Hardness of Gear: Above 45HRC

Recommend inserts: PCBN Inserts, PCD Inserts, Solid CBN Inserts, Full Face solid CBN Inserts, Compound CBN Inserts

Process Continuous: Continuous machining, Light-interrupted machining, Interrupted machining; Finishing, Roughing

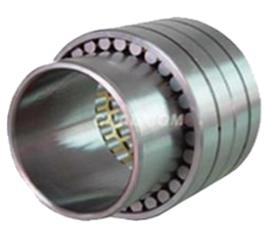

Materials of Bearing: Hardened Steel, High hardness Steel, bearing Steel, 42CrMo4, Powder metallurgy, Composite Materials and so on.

Type of Gear: Wind power bearings, industrial bearings, metallurgical bearings, wheel hub bearing units,

Gear Industry: Wind power industry, automotive industry, transportation industry, etc.

Recommend inserts

|

|

|

|

|

RNGN CBN inserts | RNMN CBN inserts | RCMX-V CBN inserts | RCMN CBN inserts | DNGA CBN inserts |

|

|

|

|

|

WNGA CBN inserts | CNGA CBN inserts | TNGA CBN inserts | VCGW PCD inserts | Diamond Bearing Strut Block |

Recommend Grade

Grade | Process Type | AP | Process Condition | Process Steel |

BN-H200 | Roughing, Finishing | 1mm--10mm | Continuous- Light Interrupt | Steel |

BN-S200 | Roughing, Finishing | 1mm--10mm | Continuous - Light Interrupt | Steel |

BN-H20 | Finishing | ≤1mm | Continuous - Light Interrupt | Steel |

BN-H11 | Finishing | ≤1mm | Continuous | Steel |

BN-H50 | Finishing | ≤0.5mm | Continuous - Light Interrupt | Steel and Powder metallurgy |

BN-H05 | Finishing | ≤0.2mm | Continuous | Steel |

BN-H10 | Finishing | ≤0.5mm | Continuous - Light Interrupt | Steel |

BN-H21 | Finishing | ≤0.5mm | Interrupt - Heavy Interrupt | Steel |

BN-H05 C25 | Finishing | ≤0.2mm | Continuous | Steel |

BN-H10 C25 | Finishing | ≤0.5mm | Continuous - Light Interrupt | Steel |

BN-H21 C25 | Finishing | ≤0.5mm | Light Interrupt - Heavy Interrupt | Steel |

CDW010 | Finishing | ≤0.2mm | Continuous | Composite Materials |

Recommend Process Parameter

Process Materials | Process Parameter | Process Condition | ||

Vc(m/min) | Ap(mm) | Fr(mm/r) | ||

High Hardness Steel | 50-150 | 1mm--10mm | 0.1-0.5 | Roughing |

90-250 | ≤1 | 0.05-0.35 | Finishing | |

Processing case

Process Wind power bearing

| Processing part: Wind power bearing, outer ring rib |

Processing size: 2750mm | |

Material and Hardness: 42CrMo4, HRC58-63 | |

Surface Roughness requirements: Ra 0.4 | |

Inserts:BN-H200 RNMN090300 | |

Machining way:Roughing and Finishing | |

Machining parameter:Vc=190m/min Fr=0.32mm/r, Ap=1-1.5mm, S=25r/min |

Workpiece: Wind Power Bearings Materials: 42CrMo, HRC58~62, Process Way: Semi-Interrupt turning Selected Insert: BN-H10 RNGN090300 Cutting Condition:dry cutting Process parameter: Ap=1mm(Roughing), Ap=0.15mm(Finishing) Fr=0.45mm/r, Vc=145m/min |  | |||

Insert Materials | Cutting Speed | Tool Life | Efficiency | |

Halnn BN-H10 | 145m/min | 3pcs | Improve 20% | |

Other Brand | 120m/min | 2pcs | ---- | |

Processing Hub bearing unit bore and raceway

| Component: Hub bearing unit bore and raceway |

Hardness: HRC58~62 | |

Inserts:BN-H50(C25)VNGA160408 | |

Process parameter: Vc=208m/min, Fr=0.15mm/r, Ap=0.23mm | |

Roughness: ≤Ra0.6 | |

Tools life: 52Pcs | |

After coating, the smooth coating will combine with the cbn perfectly, which can obtain excellent cutting performance, improve the precision and the tool life comparing with the cbn insert without coating |

Processing powder metallurgy bearings

Workpiece: Metallurgical Bearing |  | |||

Materials: Powder metallurgy, HRC62 | ||||

Processing part: bearing outer circle and inner hole | ||||

Selected Insert: BN-H11 DNGA150408 | ||||

Processing method: dry cutting | ||||

Cutting parameters: Vc=140m/min, Fr=0.12mm/r, Ap=2.5mm | ||||

Brand | Cutting Speed | Tools life | Roughness | |

Halnn BN-H11 | 140m/min | 12 pcs/tip | Ra0.8 | |

Other brand CBN | 140m/min | 10 pcs/tip | Ra0.8 | |

Process Composite materials Bearing/Sleeve

Composite bearings consist of sliding layers made of polymers such as polytetrafluoroethylene (PTFE). Effectively solve the vibration and noise of the steering wheel of the car when the car is driving. During installation, composite bearings help compensate for mating component tolerances, without the need for expensive precision ground surfaces on the shaft.

| Workpiece: Composite bearing/sleeve |

Materials: High Hardness Composite Materials | |

Selected Insert: CDW010 VCGW 160408 | |

CDW010 is made of general-purpose PCD Grade, which takes into account good toughness and high wear resistance; if you need better wear resistance, you can choose CDW025 and CDW302 materials, which have good edge strength and edge quality. |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone