Full Name: PCD Tools Machining High hardness Composite Materials

Applicable materials: CFRP carbon fiber composite materials, glass fiber composite materials, MMC metal matrix composite materials, SiC ceramic matrix composite materials, etc.

Process Way: Turing, Milling, Drilling

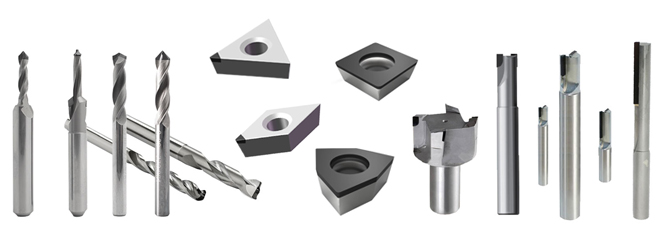

Using Inserts type: PCD Cutter inserts, PCD turning inserts, PCD milling cutters, PCD reamers, PCD drill bits, CVD diamond coated tools, etc.

Composite materials are new materials formed by optimizing the combination of material components with different properties by using advanced material preparation technology.

The matrix materials of composite materials are divided into two categories: metals and non-metals.

Commonly used metal substrates are aluminum, magnesium, copper, titanium and their alloys;

Non-metallic substrates mainly include synthetic resin, rubber, ceramics, graphite, carbon, etc.;

Reinforcing materials mainly include glass fiber, carbon fiber, boron fiber, aramid fiber, silicon carbide fiber, asbestos fiber, whisker, metal, etc.

High Hardness composite materials becase the excellent performance, are widely used in Automobile industry, aerospace industry, wind power industry, industrial products industry, transportation industry, sports equipment and other industries.

Halnn Tools can provide a variety of structured diamond tools for composite materials, efficiently process composite materials, obtain higher surface quality, and longer tool life.

Advantages of Halnn PCD Tools process High Hardness composite material

1. The special processing tools for Halnn composite materials have ultra-high hardness and ultra-wear resistance, professional edge design, maintain the geometry and sharpness of the cutting edge, long service life of the tool, and maintain the sharpness of the cutting edge to ensure product quality. Shape and dimensional accuracy.

2.Halnn PCD Tools can process composite materials with high efficiency and can avoid the tearing of composite materials; the optimized cutting edge and high-speed cutting edge design can effectively reduce cutting resistance and avoid problems such as wire drawing and fluffing.

3.Halnn PCD Tools have excellent wear resistance and maintain a sharp cutting edge, which can effectively cut fibers, ensure a high surface finish, reduce auxiliary time such as sharpening tools and polishing, reduce the labor intensity of operators, and greatly improve Productivity.

According to the processing characteristics of composite materials, Halnn recommends the process parameters as follows:

Materials | Recommend Grade | Process Parameter | |||||

Vc(m/min) | Fr(mm/r) | Ap(mm) | |||||

Reinforced plastic | CDW010 | CDW302 | CDW025 | CDW002 | 100-1000 | 0.05-0.3 | 0.1-2.0 |

composite material | CDW302 | CDW025 | CDW010 | 200-2000 | 0.05-0.3 | 0.1-3.0 | |

Process Carbon fiber composite material

Fibers are mostly added to resins, metals, ceramics, concrete and other materials as reinforcing materials to form composite materials. Carbon fiber has become the most important reinforcing material for advanced composite materials. Because carbon fiber composites have the characteristics of lightness and strength, lightness and rigidity, high temperature resistance, corrosion resistance, fatigue resistance, good structural dimensional stability, good design, and large-area integral molding, they have been widely used in aerospace, defense, military and civil industries. are widely used in various fields.

As a solution provider in the machinery industry and an advocate of environmental protection, Halnn Superhard continues to innovate independently, enhance the core competitiveness of its products, and gradually expand its service targets to various industries. Committed to providing high-quality, high-performance tool products that can meet the increasingly diverse needs of customers, so that the world will no longer have difficult-to-machine materials. For the processing of carbon fiber composite materials, Halnn Superhard has developed a new type of PCD tool, which has excellent wear resistance, edge strength and edge quality, and can efficiently process carbon fiber composite materials with longer tool life.

Halnn Superhard recommends Diamond (PCD) tools, CDW010, CDW025 and CDW302 grades of PCD tools.

CDW010 is a general-purpose PCD grade with good toughness and high wear resistance, suitable for rough and fine machining;

CDW025 is a coarse-grained PCD grade with high wear resistance and sharp cutting edge, suitable for rough machining;

CDW302 is a PCD grade with a mixed particle size of 2-30 microns. It has excellent wear resistance, edge strength and edge quality, and is suitable for rough machining processes that require higher wear resistance.

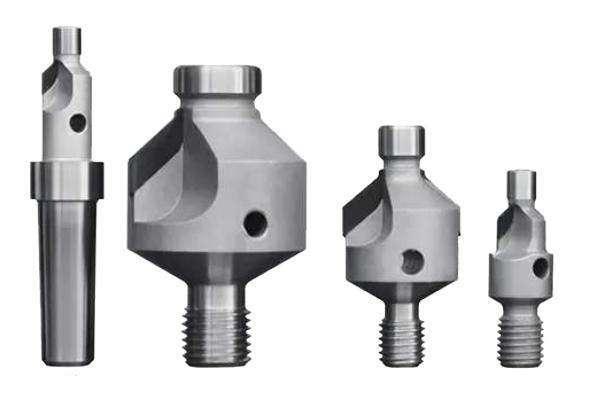

Halnn PCD drills can better drill into and out of reinforced carbon fiber composite materials, reducing the delamination trend of carbon fiber composite materials. In order to better cut carbon fibers, this type of tool can be used to weld PCD in solid carbide drills. In order to obtain better wear resistance, it can maintain the sharpness of the tool for a long time during the processing.

Carbon fiber composite drilling tools: diamond PCD drill bit, diamond drill reamer, diamond twist drill, diamond step drill, etc., using imported PCD Black as the cutting edge, with good wear resistance, tungsten carbide as the matrix , The cemented carbide substrate has good rigidity and dimensional accuracy, which can ensure the machining quality of drilling and milling, and the internal cooling (internal spiral cooling) channel is designed to improve the cooling performance. It is very important to improve the processing efficiency, which is very important for the drilling processing of carbon fiber composite materials.

Process Fiberglass Composite

Glass fiber composite material has the advantages of low density, high hardness and high strength, but the material is difficult to cut, has poor thermal conductivity, severe tool wear, low processing efficiency, and deteriorated cutting conditions. For example, in the cutting process of resin-based glass fiber composites, the main factors affecting tool life are cutting heat, friction and cutting pressure of the cutting edge, while the hard particle glass fibers in resin-based glass fiber composites are similar to those in grinding wheels. Abrasives are used to grind the tool, resulting in accelerated tool wear and deterioration of cutting conditions. Moreover, due to the requirements of some special parts, coolant cannot be used in cutting, which brings greater difficulty to cutting.

The performance of the Halnn PCD tool is very stable. The surface finish of the processed parts is good, dry cutting and wet cutting are acceptable, and the finish of the processed parts can meet the requirements without abrasive cloth polishing, which greatly reduces the labor intensity of the operator. At the same time, sharpening the tool, Auxiliary time such as polishing is also greatly reduced, reducing processing costs

Application Case - Wind Turbine Blade Tool Solution for Typical Application of Composite Materials

Wind power blades using glass fiber reinforced composite materials are much better than traditional aluminum, steel, and wood in terms of performance, wear resistance, high temperature resistance, and corrosion resistance, and are the main materials used in the wind power industry. one. Among them, the diamond tool scheme for processing glass fiber wind turbine blades is as follows:

(1) Blade root processing: reaming blade with PCD CDW010 Grade, commonly used models are: WCMT06T3, WCMT0905

(2) Milling of the end face of the blade root: After the blade root is sawed, the surface is not flat, and the end face of the root of the wind turbine blade needs to be milled with a diamond milling blade. Common blade models: CDW010 Grade SEHT1204 and SPMT16T4.

(3) Wind power blade Special Drilling Tools: Diamond electroplating reamer

Long life,reducing customer processing cost

There is no burr in the orifice,which improves the surface quality of the workpiece.

PCD center drill for smoother chip removal

PCD drill integrated roughing and finishing, and is used in drilling and milling to save processing time and improve processing efficiency

Products can be customized according to customer needs

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone