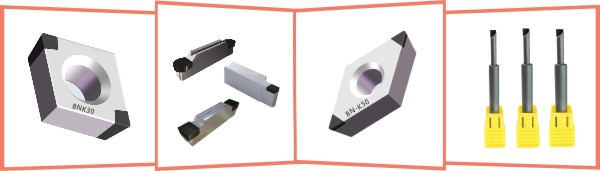

Description: Powder Metallurgy Special CBN Inserts, CBN cutting inserts

Recommend Grade: BN-K50, BNK30, BN-K10, BN-H21, BN-H101 etc

Machining Materials: Powder Metallurgy

Processing Way: Turing, Milling, Boring, Grooving

Due to the existence of porous structure of powder metallurgy, the hardness value of powder metallurgy fluctuates in a small area, even if the measured macroscopic hardness is HRC20-35, the hardness of the particles after forming the parts will be as high as HRC60. These particles will cause the tool edge The mouth wears sharply. For powder metallurgy, Halnn Tools provides BN-K50, BNK30, BN-K10, BN-H21 brand PCBN inserts for customers to choose, the specific structure is as follows

Powder metallurgy cbn inserts Recommend Tools

Process Parameters

Processing material | Vc(m/min | Ap (mm) | Fr(mm/r) | Brand |

Powder metallurgy | 80-150 (Roughing) | ≥0.5mm | 0.1-0.5 | BNK30, BN-K10, BN-K50, BN-H21, BN-H101 |

90-350 (Finishing) | ≤0.5mm | 0.1-0.2 |

Application Cases

Workpiece: Powder metallurgy |

|

Processing part: Gear - Outer face | |

Workpiece hardness: HRC20-30 | |

Blade model: BN-H101 DCGW11T302 (E01) | |

Cutting parameters: N=1900R, Fr=0.13mm/r, Ap=0.1mm | |

Processing life: 600-700 Pcs | |

Conclusion: BN-H101 high cost-effective material processing powder metallurgy has a life span of 40% longer than competing products, and the price is absolutely superior |

| Workpiece: Belt pulley | ||

Material: Powder metallurgy, HRC38 | |||

Process Condition: Semi-Interrupt cutting | |||

Insert Model:BN-K50 DCGW11T304 | |||

Cutting Parameter:Ap=0.2mm,Fr=0.1mm/r,Vc=150m/min, | |||

Dry Cutting | |||

Insert material | Roughness | Lifetime | |

Halnn BN-K50 | ≤Ra0.8 | 450pcs | |

Other Brand PCBN | Ra1.0 | 300pcs | |

Workpiece: Valve seat |  | |||

Material: Powder metallurgy | ||||

Process Condition: Semi-Interrupt cutting | ||||

Insert Model:BN-K50 DCGW11T304 | ||||

Cutting Parameter:Ap=0.05mm, Fr=0.03mm/r, Vc=160m/min | ||||

Dry Cutting | ||||

Insert material | Roughness | Cutting Speeds | Lifetime | |

Halnn BN-K10 | ≤Ra0.8 | 160m/min | 400pcs | |

Other Brand PCBN | Ra1.0 | 130m/min | 280pcs | |

WhatsApp:8613271562251

Email:service@halnn-group.com

Address:R & D 5B, National University Science and Technology Park, National University, Changchun Road, Zhengzhou High-tech Zone